Finding higher performance

How skarnes, inc. valided a change of mediant impacting system simulation

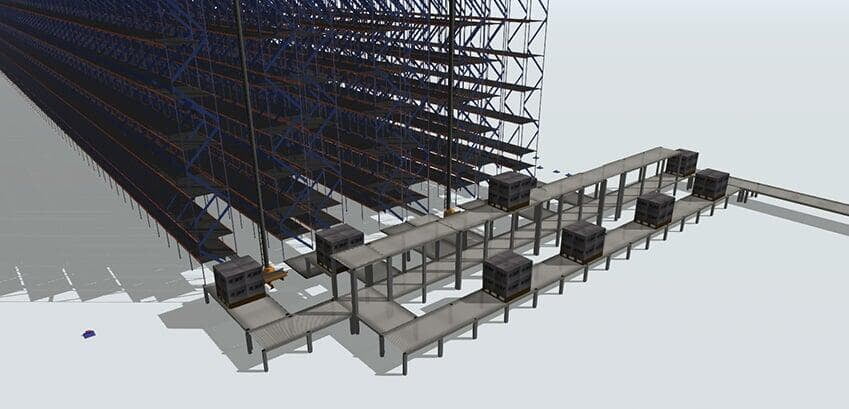

A study of an automated storage and recovery system using FlexSim simulation software. A FlexSim model builder created a system simulation model to validate the proposed changes to the installations, resulting in improved warehouse efficiency for the end customer.

Skarnes Inc., an integrator of material handling systems located in Plymouth, Minnesota, wanted to increase the performance of one of his customer's storage processes. The customer used an automated storage and recovery system (AS/RS) that interacted with a conveyor circuit, transporting pallets to a collection station and then back to the AS/RS.This system was capable of collecting 70 pallets per hour and Skarnes studied it for possible improvements.

Problems to resolved

- The simulation showed that the changes would result in a 43% improvement in performance.

- After observing this operation, Skarnes assumed that the number of pallets collected per hour would increase if congestion could be reduced in front of the AS/RS. Skarnes came up with the idea of adding another main conveyor for the exit pallets; this new conveyor would be located above the existing main conveyor. To demonstrate the validity of this option to its customer, Skarnes commissioned a computer simulation of the system.

Results

FlexSim developed a precise 3D simulation model to confirm Skarnes' proposal. By adding this top-level main conveyor, the simulation model showed that the number of pallets collected would increase from70 to 100 pallets per hour, an increase of 43%. The 3D animation of the system also visually confirmed that congestion of the congestion was considerably reduced, adding another level of validation for the customer.

Objectives

- Create a 3D model of an AS/RS and a conveyor circuit.

- Validate the effectiveness of adding a main conveyor to the system.

Results

- The number of pallets collected would increase from 70 to 100 pallets per hour,43% increase in performance.

- Visual validation that congestion of the congestion would be considerably reduced.

"This simulation model was an invaluable tool for our project. FlexSim was professional and easy to work with".Matt Thibodeau,Sales Engineer -Skarnes, Inc.