Properly organize and sequence orders

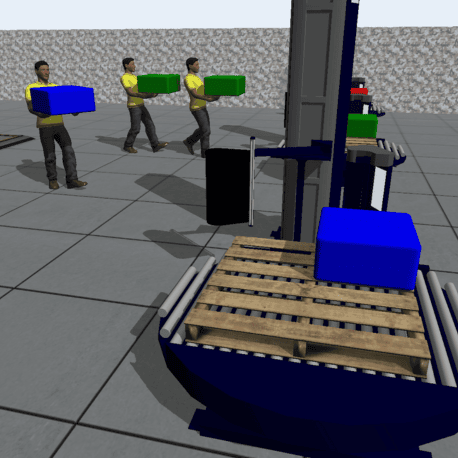

In automated distribution centres, properly organizing and sequencing orders is key to ensuring products come out on time.

With so many interactions and dependencies involved in current warehouses, a simulation study is an effective option to understand and help balance these systems.

For Bastian Solutions, simulation modeling was a critical component of helping your cosmetics distribution customer design and implement a highly automated distribution center. The aim was to create a functional simulation model of the facility for use as a decision-making support tool. Bastian Solutions and their talented team of engineers did just that: they built a 3D simulation model using FlexSim simulation software.

Overcoming challenges

Bastian Solutions overcome a number of challenges they encountered in modeling such a complex facility. The model needed to manage 40,000 rows of SAP data and associate this data with elements in FlexSim. This is a good amount of data to manipulate. To resolve this problem, Bastian used FlexSim's integrated SQL functionality to write a series of queries that made the data meaningful and usable in the model.

Objectives

Create a functional simulation model as a decision support tool.

Investigate changes in:

- Slotting products.

- Order volumes/mixing orders.

- Workload balance.

- Logic of warehouse control system.

- Staff plans and programming.

- Operator productivity.

Results

Valuable decision-making support tool, now and in the future.

Ability to answer questions about:

- Current state of the system.

- Information on daily events.

- Usage and work rates.

- Balance of areas and areas.